Tell us about your role at Aleph Farms.

I am a senior R&D manager at Aleph Farms.

At Aleph, we have a half dozen teams within R&D. My group took pluripotent starter cells from our cell bank and differentiated them into the cells that produce collagen. The end result of our process is a cultivated collagen-rich biomaterial that serves as a raw material for end products in different industries.

In addition to cultivating the biomaterial itself, we play an active role in co-developing end products with partner companies.

So you’re not really dealing with the cultivated beef steaks that Aleph is known for?

It’s tempting to view Aleph as a cultivated meat company. While Aleph is of course a major player in the cultivated meat ecosystem, we’re actually a cellular agriculture company. Cultivated meat is but one application of cellular agriculture. As a new category of animal products, the animal cell has numerous applications other than cultivated meat. I definitely feel that my team’s work with collagen is a testament to this wider scope.

On the one hand, we’re a young company, so it’s important to focus, and given cultivated meat’s potential impact in terms of ensuring food security, protecting the climate and preserving biodiversity, I understand that focus.

On the other hand, we think big. We’re out to solve some of humanity’s biggest problems, so we have to think ahead. Aleph Frontiers, our deep-tech incubator, lets us complement our focus on cultivated beef steaks with a far-thinking approach. Our cultivated collagen-rich biomaterial is the first product to emerge from Aleph Frontiers and I’m very proud of that.

Tell us about collagen. What makes it important?

People use and encounter products with collagen all the time. Beyond leather and other conventional animal products rich with naturally occurring collagen, it’s common in food supplements, in the world of cosmetics, and of course in medicine. Collagen is an important part of skin grafting, wound healing, tissue regeneration, and various other medical applications.

At Aleph, we are currently exploring potential use cases for our cultivated collagen-rich biomaterial with partners in the medical space.

We bet most people don’t even think about the collagen they encounter.

For sure. There’s a huge disconnect, even greater than the disconnect with food. My colleague Olivier Metzger, a fourth-generation butcher, rightly pointed out “the distance between the animal and the diners” – how a few generations ago, we were familiar with each and every animal we ate, and how now, “the first time most of us encounter the animal is when we open our menu.”

With collagen, the disconnect is even greater. I know people who don’t eat meat and refrain from products that were tested on animals but do use products with animal collagen in them, if for no other reason than they are unaware that the products include animal ingredients.

How does cultivated collagen compare to conventional collagen?

Cultivated collagen has some key advantages, especially in a field like medicine, where the threshold for quality is especially high.

Most conventional collagen comes from the hides and bones of slaughtered animals. The standard process that releases the collagen from these hides and bones involves soaking them in an acidic solution. A consequence of this process is denaturation, which is when the structure of proteins changes. As a result of this undesired structure modification, collagen loses the biophysical properties necessary for medical applications.

Overall, extracting collagen from animal parts makes the collagen prone to contamination (from bacteria), inconsistency (it could differ, ever so slightly, from animal to animal) and low levels of purity (other matter is invariably mixed in).

By contrast, we start with cow cells, not an entire carcass. We start with everything we need and don’t have to spend time and resources sorting out unwanted factors. This creates clear added value for the medical field. In addition, our cultivated collagen-rich biomaterial includes glycoproteins, proteoglycans and glycosaminoglycans like hyaluronic acid, which further contribute to regeneration and healing.

But can’t those medical applications use something other than collagen?

Not always. There isn’t always a cost-effective 1:1 replacement. This opens the door for cultivated collagen to step in, and from our discourse with medical professionals, there seems to be plenty of opportunity in this regard.

And because conventional medical technology is expensive, cultivated collagen’s road to price parity is shorter than that of cultivated meat and other applications of cellular agriculture.

What is the most rewarding part of your work?

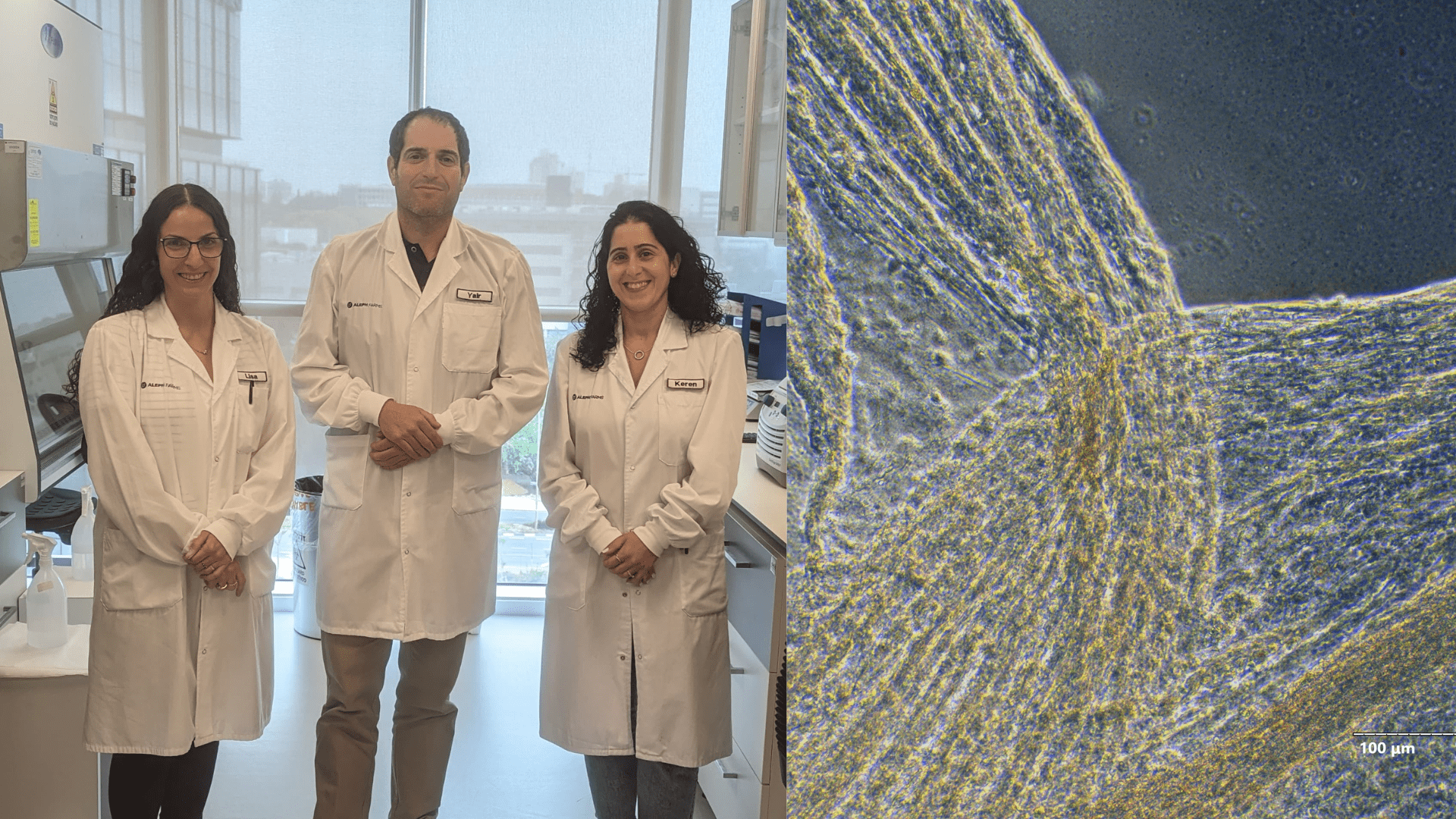

I’d say it’s being surrounded by people who live and breathe science – cell biology, biochemistry, material science, and much more. We harness diverse branches of science to achieve practical solutions to unmet medical needs. When I started at Aleph, the first thing I set out to do was build a team. Dr. Keren Tazat Fireberg was my first hire. A cell biologist by training, she came on to lead this aspect of our team’s work and we’re still going strong.

R&D is all about asking questions and finding answers. It’s about thinking together and out of the box. My team has filed several patents so far because we have embraced this attitude.

I am grateful for the rich culture of teamwork and collaboration we have at Aleph Farms, and I do my best to foster that culture whenever and however I can.

Things became especially difficult in Israel on and after October 7th. How has this impacted your work?

It’s impacted my entire life – work included, but so much more.

I am married with four kids and think about my family’s safety every day. Right after the Hamas massacre on October 7th, I was called up to military reserves, where I serve in the armored core. I spent 4.5 months in the first line of fire on Israel’s northern border – very tense times, indeed.

But life goes on, and in Israel, we know a thing or two about persisting in the face of serious adversity. My teammates didn’t miss a beat while I was up north and made sure that everything stayed on schedule. Aleph Farms and the country’s entire technology sector are forging ahead no matter what.